Tradition Precision Innovation

Alfons Haar takes DRD into new dimensions

Hamburg, January 16, 2019 - For as long as one can remember there has been a rule limiting two-piece Draw & Redraw (DRD) food cans to so-called shallow drawn cans with a diameter exceeding or at least matching the height of the can.

The most famous example is the 83x86mm sized can of vegetable canner Bonduelle, which was initially designed to fit this rule.Drawn and wall ironed (DWI) cans as an alternative did not pick up due to the size of the machinery and the limited ironing potential of sanitary cans compared to beverage cans for carbonated content.

Consumers worldwide become increasingly sensitized about food security. The growing public awareness of possible health risks due to migrating internal lacquers brought new factors into play. For decades, bisphenol A (BPA) has been widely used in the inside lining of cans, to prevent metal corrosion and breakages, preserving the food inside.

EU regulations, like e.g. (EC) 2018/213, address food safety concerns due to lacquer migration. The European Food Security Authority (efsa) has been evaluating BPA toxicity for years, constantly analyzing new data and making updated assessments. As one of the results, the Tolerable Daily Intake (TDI) for BPA has been constantly lowered over the years (source). As analytical techniques improve, more regulations are to be expected.

Increasing market demand for plasticizer-free food packaging and the need to comply with EU regulations lead to new developments in the food industry. Alfons Haar has already successfully launched liners for migration-free products for closures (Lug Caps, PT, PP), using thermoplastic elastomer (TPE) sealing instead of PVC compounds.

For sanitary cans we focus on drawn cans made from laminated steel to prevent contamination by internal lacquers (BADGE) and welding seam repair issues. These 2-pc cans break the rule of the diameter - height relationship and allow our customers to eliminate the migration issue.

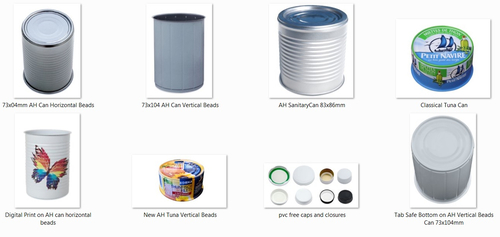

Alfons Haar now presents newly developed cans and equipment on this basis. Shallow DRD cans made from laminated steel have been used successfully for years, mainly in Japan. Alfons Haar will now deliver a DRD line, for 73x104 mm cans with an output of 400cpm. The filler is a major manufacturer of processed milk.

Also produced on Alfons Haar machines is the thinnest commercialized 2-pc tuna fish DRD can in the market at 0.14 DR8, representing 20% metal savings, equal to more than 1,000,000 $ per line and year. This is possible with our patened side wall bead design combined with the the tab safe bottom. The new bottom design gets its name from preventing unintended opening when stacking on ezo ends.

The wall beads, initially intended to be covered by paper labels, turned out to be a marketing feature. Even readable bar code can be printed on, using direct printing. For shallow drawn cans, well developed distorted printing is not applicable. Digital printing is developing into a genuine alternative.

Available Picture Material:

High resolution pictures will be provided upon request.

Background information:

About Alfons Haar Maschinenbau

Alfons Haar Maschinenbau GmbH & Co KG was founded in 1949 by Mr. Alfons Haar and is based in Hamburg, Germany. Alfons Haar is the inventor and market leader of modern CNC sheet feed presses for the metal packaging industry. Based on these presses Alfons Haar offers complete lines for the different applications of sanitary and easy open ends, closures (Lug Caps, PP and PT caps), drawn cans (DRD) and components for general line made from aluminium and steel. Alfons Haar is a global player with operations in Europe, America, the Middle East, Africa, and Asia. The group continues to expand in the second and third generation of family management. Managing director is Mr. Thomas Haar.

DRD expertise

Draw – Redraw Lines (DRD) have been one of Alfons Haar’s strong suits since 1982. Our presses run aluminum, SR-, DR-, tin and TFS plate with optional lamination. We can do square or scroll cut with sheet sizes up to 1000 x 1200 mm. We guarantee a clip out and scratch free operation, high precision for printed products and highest flexibility for a fast changeover. The capacity is up to 900 cans per minute.

More information on https://www.alfons-haar.de/products/2-pc-cans/

Media Contact:

Cornelia Haar

Marketing Manager

Phone: +49 40 83391 148

Email: cohaar@alfons-haar.de