Tradition Precision Innovation

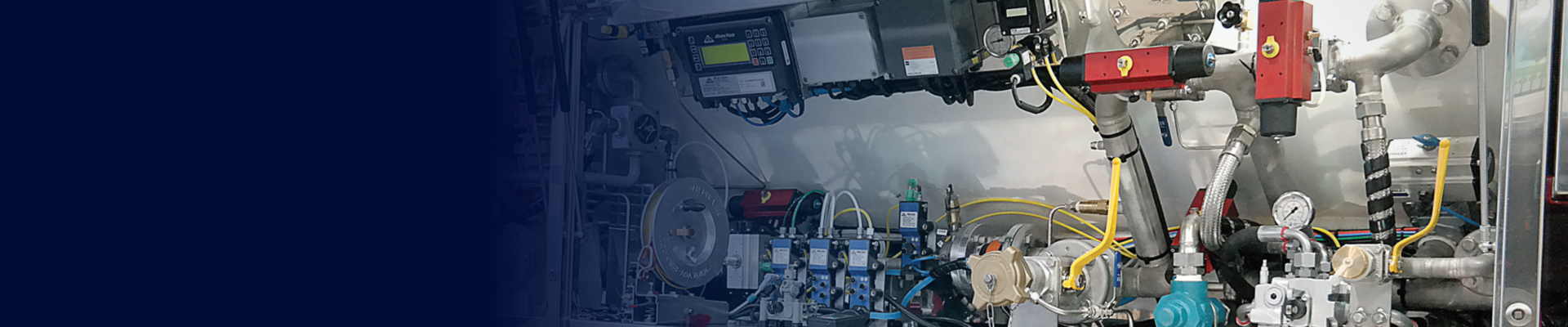

Integral LPG Tanker Solution PreciGAS

PreciGAS – the 1st. choice for a reliable accurate and wear free LPG metering solution.

- ATEX approved (natively by design, heavy Ex-d enclosures and discrete intrinsic safety barriers not required)

- Suitable for Butane and Propane LPG’s and all mixtures

- 1 or 2 LPG hose reel support with one flow meter

- PreciGAS C 400 – typically used for domestic LPG deliveries at 25 to 400 l/min

- PreciGAS C 1000 – typically used for mainline LPG supplies at 60 to 1,000 l/min

Accurate - with an unbeaten PTB type approved flow rate turndown range of 16:1 these solutions are the prime of LPG ventury meters. In fact this is in average 4 times better than others.

PreciGAS Solutions are available for conventional (manual line valves) operation or market unique fully automated operation.

Automation has come to LPG Tankers

Designed with ease of use in mind.

No driver valve handling, removing risk of running pumps dry.

- Drivers simply select the required mode of operation and PreciGAS will manage all aspects of your tanker as required, including engine start/stop, PTO engagement, pump or compressor activation and all valves. Additionally, the whole process can be performed by remote control.

- Included are automated operations with any available legacy draw-bar trailer. The functionality includes self-loading from trailer to motor wagon or direct delivery from the trailer through the motor wagon, incl. trailer hose priming management.

- The maximum pre-set volumes are automatically suggested to the driver considering selectable/configurable standard tank sizes and (also remote control) entry of current filling levels to prevent overfill and optimizing the delivery service. Risk of manual miscalculations, misuse or bypassing of overfill prevention system are greatly reduced.

The delivery system provides litres or kg with real-time measurement of volumes, temperature and density information, thus enabling matching volume (delivery) vs mass (loading) balance sheets.

Modern competitive thinking of LPG Tanker system design

The new approach is an integral LPG Tanker solution considering all system aspects from building a tanker to operation and maintenance in the real world.

Building a tanker

- ATEX certification comes as a standard, enabling direct cabinet integration

- Easier assembly with a complete factory pre-manufactured metering line (perfect for new builds and upgrades)

- PreciBUS and PreciNODE connectivity avoiding any junction box and excessive wiring

- Immediately ready for testing after installation with integrated time saving field bus diagnostics and intelligent fault analysing

Operating modern LPG Tankers

Technology for simplicity!

- Simple driver operating mode selection enables also less experienced drivers a perfect control

- Full remote control with the OLED display featured WiPIT

- Automated pre-set calculation/suggestion

- Automated LPG type sensing and name selection

- Automated valve management for loading and deliveries including compressor operations

- Chassis interfacing for automated diesel motor, PTO or handbrake Management

- Automated pump and compressor management

- Faster deliveries and more efficient low pressure drop flow meter element and bottom valve designs

- Overfill prevention monitoring for stationary tanks and driver safety dialogues

- Time saving remote printing, ready to go when drivers return to the tanker

- Direct individual cabinet door monitoring

LPG Inline Density Measurement

Optionally, PreciGAS provides a PTB type approved real-time product density measurement, which leaves no doubt about the real LPG grade (density according to the actual LPG composition), volume and/or mass measurements.

For any LPG mixture the PreciGAS system can automatically select the correct product (name) - drivers cannot make a mistake anymore!

Temperature changes/drifts are usually unavoidable in typical LPG tank truck delivery flow measurements. The DIS 1A sensor has an exceptionally low sensor mass and therefore natively supports the best possible step response capabilities when it comes to always time-critical consideration of temperature gradients in the mass / volumetric flow measurement of LPG.

This physical advantage over more massive vibrating density and flow sensors which require an internal steel temperature depending elastic modulo compensation (mandatory vibration correction) provides the generic key advantage in practical handling to enable a better accuracy of the complete flow measurement.

The sensor DIS 1A is mounted directly on the measuring section as a supplementary solution to the otherwise none-moving / none-vibrating core flow measurement element of the PreciGAS system.

LPG tanker fleet improvement

Integration and fleet improvement based on more reliable online information

- Bi-directional communication by the open standard FTL protocol for delivery and system events like cabinet doors opening and more

- New style LPG bottomvalve with integral physical piston monitoring supporting loss control

- Hose reel information to determine the hose length actually in use for the operator evaluations of his LPG customer sites

- Customer tank level % data prior and after delivery or vacuum services for better customer consumption planning and proof of delivery

Benefits

The core technical differential advantages with PreciGAS provide better bottom line results for fleet operators.

- Exceptional good measurement uncertainty funds the operators fiscal security

- Meter with no moving parts, essentially wear and maintenance free are the bases for stable operators cash registers

- Lowest weight design, highest actual flow rates or less diesel consumption maximizes the fleet utilisation rate and reduces the overall operating cost

- Automated driver processes for more safety and a native dry run protection reduce risk and maintenance expenditures

- Tamperproof system design with the PreciBUS, NAMUR sensory, smart logics and event log avoid unexpected loses

- No vendor trap with the open standard FTL communication for LPG tanker

Sales flyers:

The solution with a real concept along a holistic approach enabling the lowest cost of ownership.

General information about LPG transport and delivery application solutions >

Lösungen für Flüssiggas Tankwagen und Messsysteme - PreciGAS C 400/1000 >

Soluzioni integrali per Autobotti - Automazione arriva nelle Autobotti GPL>

La Solution Globale Pour Citerniers - L’automatisation arrive chez les citerniers GPL >

Soluciones Integrales para Camiones Cisterna- La automatización ha llegado a las cisternas de GLP >

Discover more:

WiPIT delivery system remote control >

AS-LG tank overfill prevention monitor >

LPG tanker bottom valve GPBV 80 >

ALUette - hose reels for LPG, mineral oil products and water >

Consult factory for more details about the PreciGAS C 400/1000 - LPG metering system.

Online system configuration and P&ID builder for registered webshop users only.